- Properties

- Application

- Standard Specification

- Packing and Storage

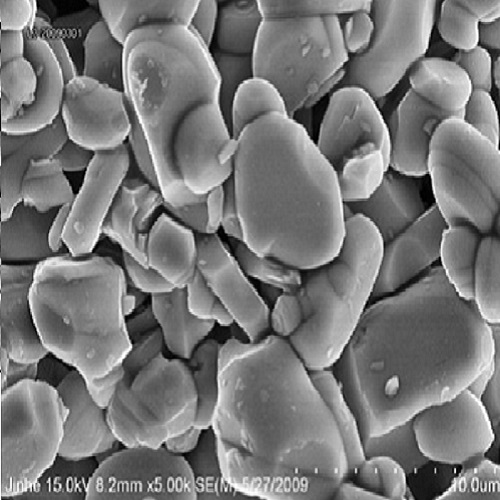

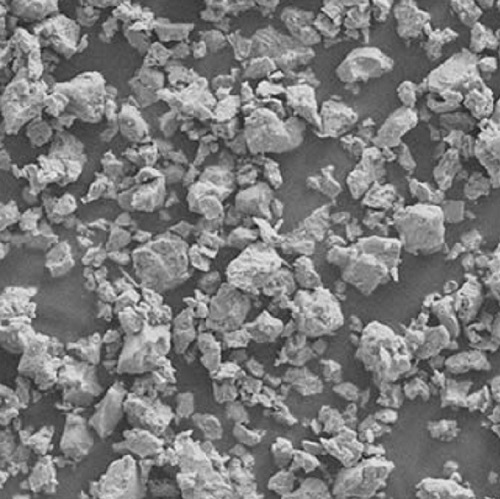

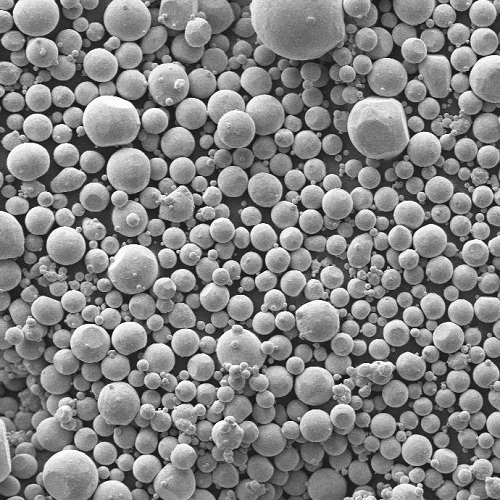

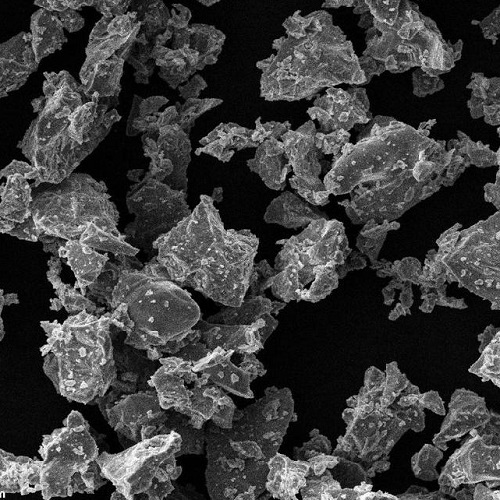

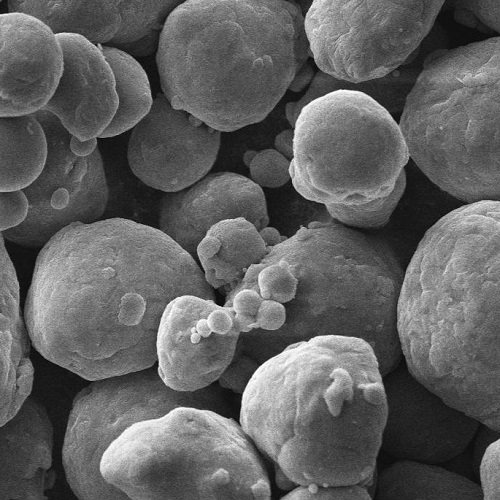

CNPC POWDER Lead powder used atomized productiong process with high purity lead ingots. It has gray color and spherical shape, In moist air it has easy oxidation. We supply different particle size for customer requirment.

Lead Powder Production Process

Step 1: High Quality Lead Material

Step 2: Melting

Step 3: Atomized

Step 4: Filter

Step 5: Collect

Step 6: Dry

Step 7: Grading

Step 8: Inspection

Step 9: Packing

Lead Powder Applications;

- Powder metallurgy industry.

- Chemical industry

- Diamond tools

- Hard alloy

- Bronze bearing self-lubricated

- Structural parts

- Friction discs

- Brakes

- Clutches

- Electric carbon brush

- Bronze filtersAdditives of rubbers and plastics

- Chemicals

| Grade | Composition (%) | O(%) | A.D.g/cm3 | Particle Size | ||||

|---|---|---|---|---|---|---|---|---|

| +100(150μm) | +140(106μm) | +200(75μm) | +325(45μm) | -325(45μm) | ||||

| CNPC-Pb200 | Pb 99.9 | 0.3max | 4.5-6.0 | - ≤1 ≤5 ≤30 Bal | ||||

| CNPC-Pb300 | 0.3max | - - - ≤10 Bal | ||||||

| Grade | Package |

|---|---|

| CNPC-Pb200 | 25KG/Bag or Drum |

| CNPC-Pb300 | 20KG/Bag or Drum |

Lead Powder Storage Note:

- The lead powder should store in a cool, ventilated warehouse. Away from fire and heart source .

- It should be stored apart from oxidant acids, halogen ,mixed reservoir of avoiding by all means.

- Equipped with corresponding varieties and number of fire equipment.

- Storage area should be equipped with the right material for leakage content.

中文

中文 España

España

Download

Download