- Properties

- Application

- Standard Specification

- Packing and Storage

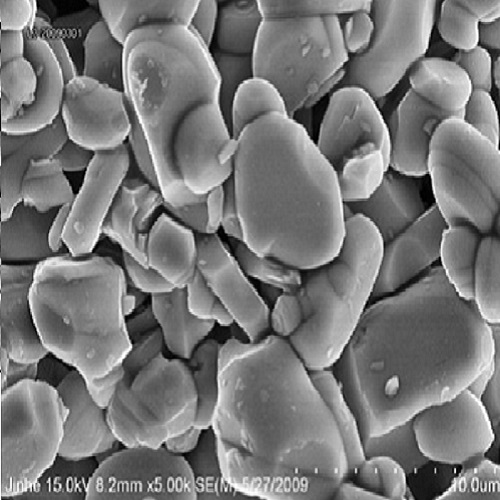

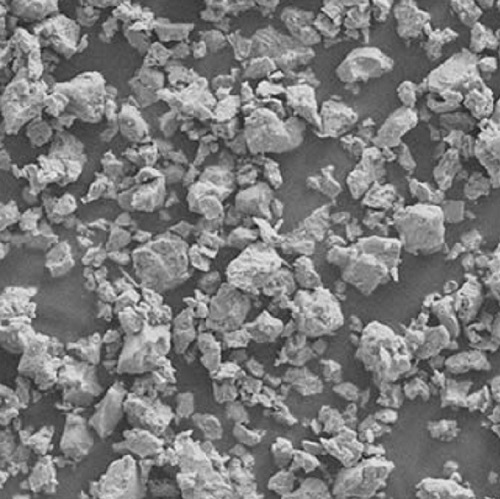

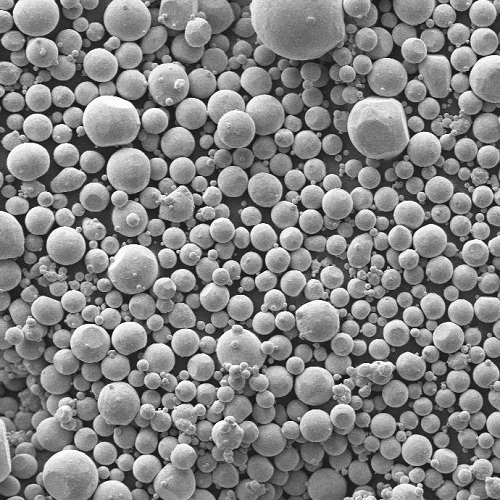

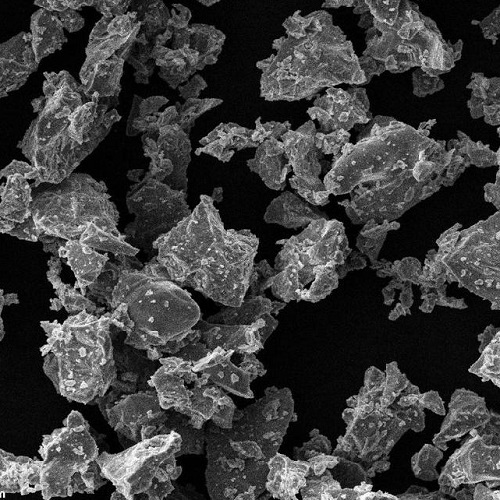

CNPC POWDER Titanium powder used pulverizing process with sponge titanium material.It has gray color and irregular shape, In moist air it has easy oxidation.It's purity around 99%.We supply different particle size for customer requirment.

Titanium Powder Production Process

Step 1: High Quality Sponge Titanium

Step 2: Jaw Crusher

Step 3: Jet Mill

Step 4: Filter

Step 5: Collect

Step 6: Grading

Step 7: Mixing

Step 8: Inspection

Step 9: Packing

Titanium Powder Applications;

- Powder metallurgy industry.

- Diamond tools

- Hard alloy

- Aerospace

- Spraying

- Fireworks

- Alloy

- Chemical corrosion resistant material

- Electric vacuum materials

- Additive in alloy

| Grade | Composition (%) | O(%) | A.D.g/cm3 | Particle Size | ||||

|---|---|---|---|---|---|---|---|---|

| +100(150μm) | +140(106μm) | +200(75μm) | +325(45μm) | -325(45μm) | ||||

| CNPC-Ti | Ti 99 | 0.3max | - | 100mesh, 200mesh, 300mesh | ||||

| Grade | Package |

|---|---|

| CNPC-Ti | 25KG/Bag or Drum |

Titanium Powder Storage Note:

- The titanium powder should store in a cool, ventilated warehouse. Away from fire and heart source .

- It should be stored apart from oxidant acids, halogen ,mixed reservoir of avoiding by all means.

- Equipped with corresponding varieties and number of fire equipment.

- Storage area should be equipped with the right material for leakage content.

中文

中文 España

España

Download

Download