- Properties

- Application

- Standard Specification

- Packing and Storage

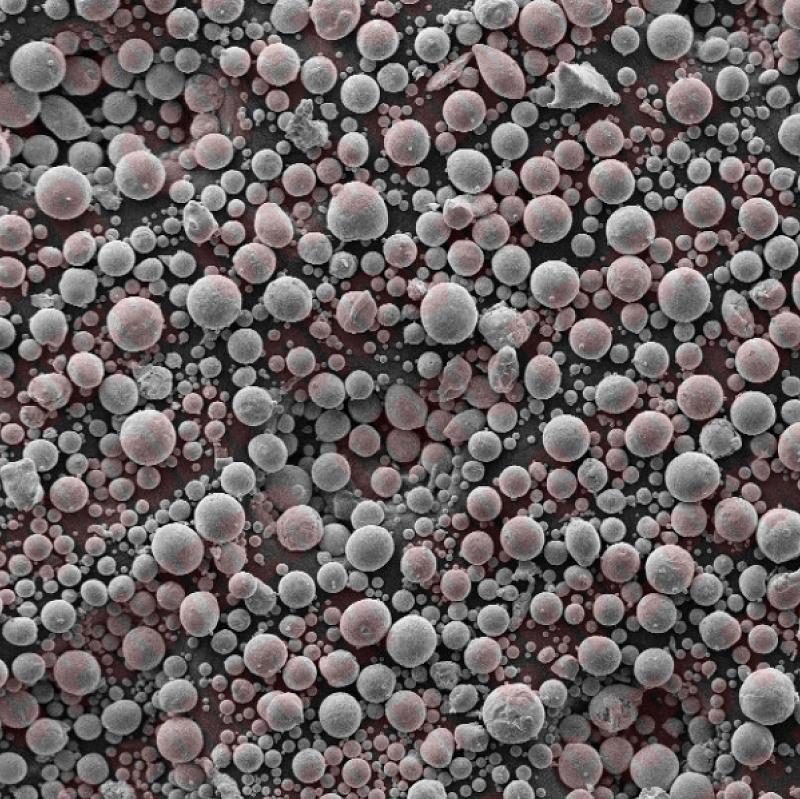

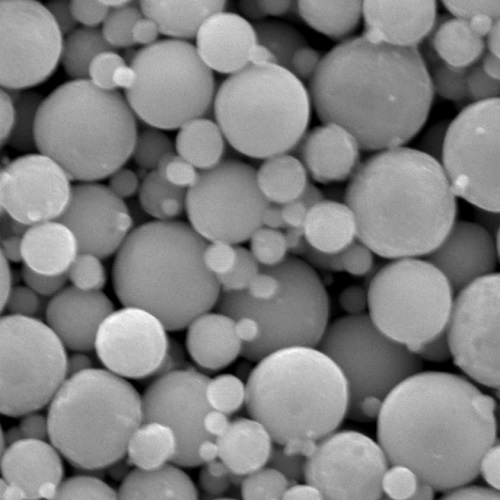

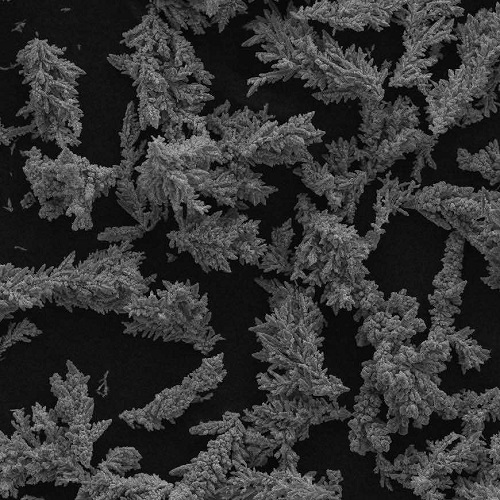

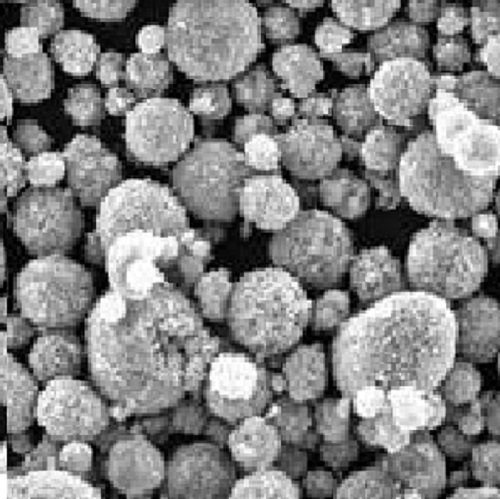

CNPC POWDER copper alloy powder (bronze powder and brass powder) with tin, zinc, lead and other elements are produced by the process of powder metallurgy. They have the physical and mechanical properties of their cast or wrought counterparts.Copper alloyed with iron powder reinforce the mechanical properties and control dimensional changes during sintering, the addition being made either by mixing or by infiltration. Copper Powders have good strength, thermal conductivity, wear resistance, color and gloss.

Copper coating iron powder is the process of plating copper on surface of the iron powder. The color is the same as copper powder. It's instead of copper powder sometimes. It's cold be reduce the cost.

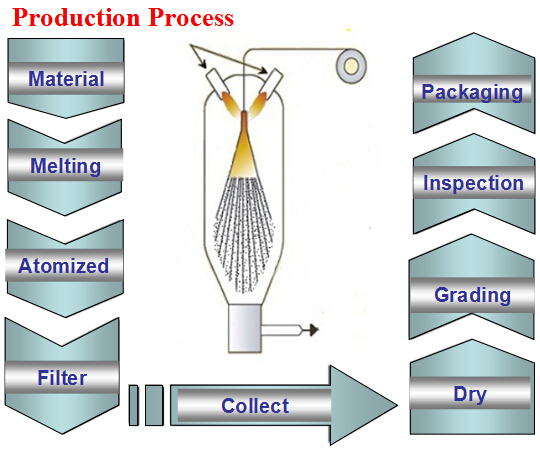

Copper Alloy Powder Production Process

Step 1: High Quality Cu Sn Zn Pb Material

Step 2: Melting

Step 3: Atomized

Step 4: Diffusion

Step 5: Filter

Step 6: Dry

Step 7: Grading

Step 8: Inspection

Step 9: Packing

Copper Alloy Powder includes copper tin alloy powder

(bronze powder), copper zinc alloy powder (brass powder)

copper iron alloy powder, copper lead alloy powder etc.

Copper Coating iron Powder includes copper coating

iron powder, bronze coating iron powder, brass coating

powder. This is best material used in Oil bearing bushing.

| CAS no.: | 744-50-8 |

|---|---|

| HS code: | 7406209000 |

| Molecular Formula: | Cu |

| Color: | Light Rosy |

| Shape: | Irregular or Spherical shape |

| Purity: | Cu Sn Zn Pb |

| Product method: | Water and Gas Atomization |

| Molecular Weight: | 63.55 |

| Freezing/Melting Point: | 1083.4℃ |

| Boiling Point: | 2567 ℃ |

| Specific Gravity/Density: | 3.0-3.5g/cm3;4.5-5.2g/cm3 |

| Applicable Solubility in water: |

Slightly soluble in hot water |

- Main material in powder metallurgy industry

- Oil bearings.

- For antiseptic substance in food packing and reducing agent.

- Diamond tools.

- Friction materials

- Coating

- Plastic composite filling

- Cold spraying and the thermal spraying

- Best choice for welding materials, hard alloy, electric conductive slurry etc.

| Grade | Composition (%) | O(%) |

A.D. g/cm3 |

Particle Size | ||||

|---|---|---|---|---|---|---|---|---|

|

+100 (150μm) |

+140 (106μm) |

+200 (75μm) |

+325 (45μm) |

-325 (45μm) |

||||

| CNPC-CuSn | CuSn10,CuSn15,CuSn20 | 0.3max | 3.0-3.8 | 100mesh, 200mesh, 300mesh | ||||

| CNPC-CuZn | CuZn20,CuZn30,CuZn40 | |||||||

| CNPC-CuFe | CuFe70 | |||||||

| CNPC-CuPb24Sn1 | Cu75,Pb24 Sn1 | |||||||

| CNPC-CuNi30 | Cu70, Ni30 | |||||||

| CNPC-CuSn6Zn6Pb3 | Cu85, Sn6, Zn6, Pb3 | |||||||

| CNPC-CuSn10Pb10 | Cu80, Sn10, Pb10 | |||||||

| Grade | Composition (%) | O(%) |

A.D. g/cm3 |

Particle Size | ||||

|---|---|---|---|---|---|---|---|---|

|

+100 (150μm) |

+140 (106μm) |

+200 (75μm) |

+325 (45μm) |

-325 (45μm) |

||||

| CNPC-FeCopper | Cu15%,Cu18%,Cu20%,Cu30% | 0.3max | 2.3-2.5 | 100mesh, 200mesh, 300mesh | ||||

| CNPC-FeBronze | Bronze 18%,Bronze 20% | |||||||

| CNPC-FeBrass | Brass 18%,Bronze 20% | |||||||

| Grade | Package |

|---|---|

| CNPC-CuSn | 25KG/Package |

| CNPC-CuZn | 25KG/Package |

| CNPC-CuFe | 25KG/Package |

| CNPC-CuPb24Sn1 | 25KG/ Package |

| CNPC-CuNi | 25KG/ Package |

| CNPC-CuSn6Zn6Pb3 | 25KG/ Package |

| CNPC-CuSn10Pb10 | 25KG/ Package |

| CNPC-FeCopper | 25KG/ Package |

| CNPC-FeBronze | 25KG/ Package |

| CNPC-FeBrass | 25KG/ Package |

- The Copper Alloy Powder should store in a cool, ventilated warehouse. Away from fire and heart source .

- It should be stored apart from oxidant acids, halogen ,mixed reservoir of avoiding by all means.

- Equipped with corresponding varieties and number of fire equipment.

- Storage area should be equipped with the right material for leakage content.

中文

中文 España

España

Download

Download