- Properties

- Application

- Standard Specification

- Packing and Storage

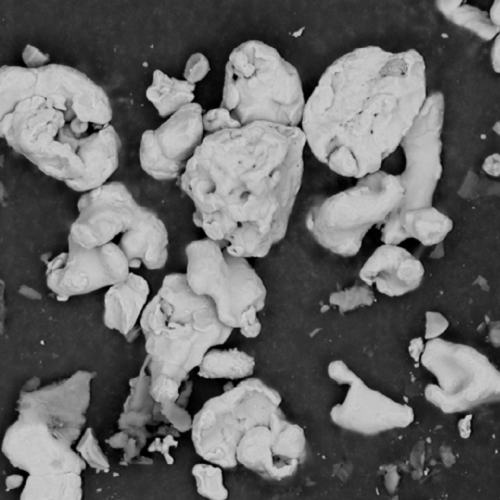

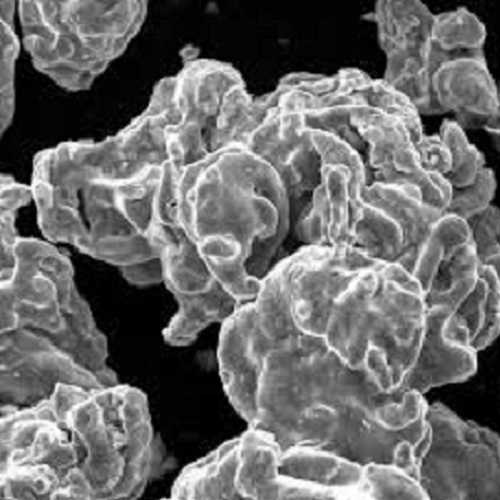

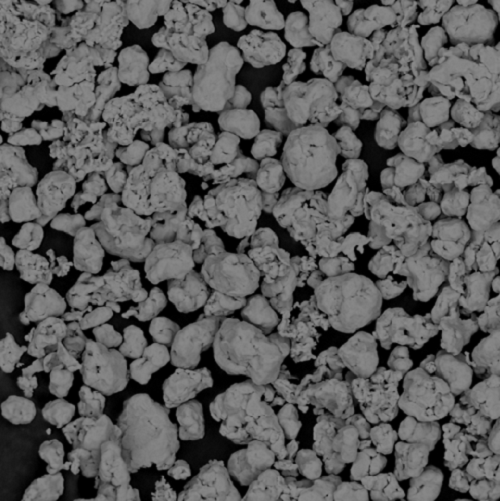

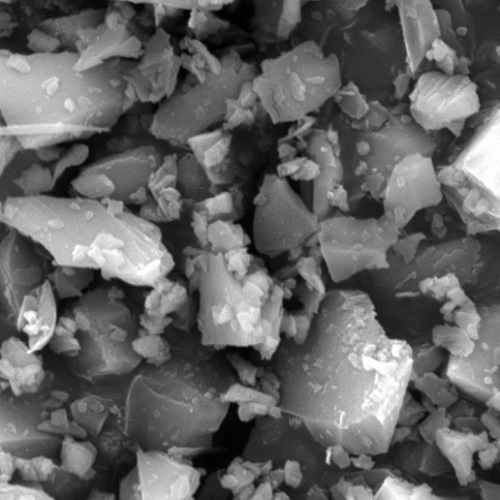

CNPC POWDER ultafine iron alloy powder contains many diffierent elements such as FeCu, FeMn, FeMo, FeCr, FeCo, FeV, FeSi, FeB and others. The product is produced mainly by method of physical crushing.

Ultrafine Iron alloy powder Production Process

Step1: High Quality Material

Step2: Crushing into small particels

Step3: Screening

Step4: Particel collision grinding powder

Step5: Air classification

Step6: Test

Step7: Packing

Some of the main uses for the Ultrafine Iron Alloy Powder;

●Main material in powder metallurgy.

● Diamond tools.

● Hard alloy etc.

●Main material in powder metallurgy.

● Diamond tools.

● Hard alloy etc.

| Grade | Composition (%) | Physical Properties | Particle Size(%) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fe≥ | C≤ | S≤ | O≤ | AI≤ | P≤ | Mn≤ | Si≤ |

A.D. g/cm3 |

GD600 g/cm3 |

Flow, sec/50g |

+100 (150μm) |

+200 (75μm) |

+325 (45μm ) |

|

| CNPC-FeCu | Fe 90, Cu 10 | 1-1.8 | D50: 4-8μm D50:8-12um | |||||||||||

| CNPC-FeMo | Fe bal Mo 60-65 | 1-1.8 | ||||||||||||

| CNPC-FeCr | Fe bal Cr>60 | 1-1.8 | ||||||||||||

| CNPC-FeMn | Fe bal Mn>75 | 1-1.8 | ||||||||||||

| CNPC-FeV | Fe bal V>50 | 1-1.8 | ||||||||||||

| CNPC-FeB | Fe bal B>18 | 1-1.8 | ||||||||||||

| Grade | Package |

|---|---|

| CNPC-FeCu | 25KG/Package |

| CNPC-FeMo | 25KG/Package |

| CNPC-FeCr | 25KG/Package |

| CNPC-FeMn | 25KG/ Package |

| CNPC-FeV | 25KG/ Package |

| CNPC-FeB | 25KG/ Package |

| CNPC-FeSi | 25KG/ Package |

Storage Note:

The iron powder should be stored in a cool, dry, well ventilated warehouse and kept away from fire and other heat sources. Relative humidity should remain below 75%. The packing must be sealed, do not be affected with damp . It should be kept apart from alkali, alcohol, and it should avoid mixed reservoir by all means. The storage area should be equipped with the right material in the case of leakage.

中文

中文 España

España

Download

Download