- Properties

- Application

- Standard Specification

- Packing and Storage

CNPC POWDER utilizes the best magnetite with the lowest impurity found in China. After serval processes with strict quality control,the raw material becomes high purity (99.1%-99.5%) iron powder with very low impurity content of C, Si, Mn, P and S .

Iron powder Production Process

Step 1: High Quality Magnetite Selection

Step 2: Mineral Processing

Step 3: Drying

Step 4: Primary Reduction

Step 5: Crush

Step 6: Screening

Step 7: Secondary Reduction

Step 8: Mesh Screening

Step 9: Batche Blending (20Ton)

Step 10: Packing

We supply different purity of reduced iron powder(sponge

iron powder),such 99%,98.5%,98%,97%,96%

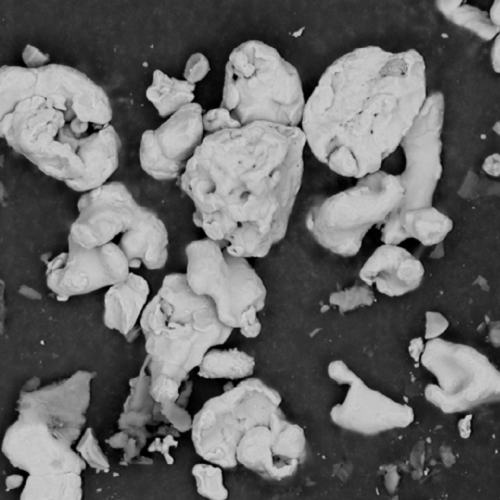

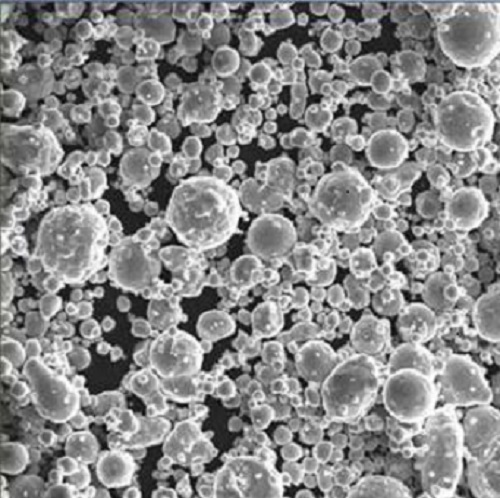

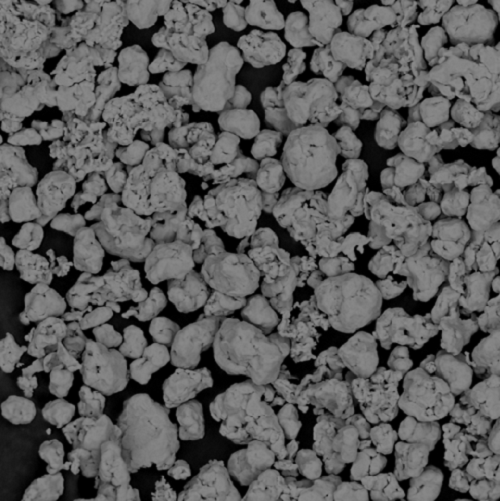

Reduced Iron Powder is usually produced by reducing the

oxide part (such as iron ore, rolled steel scales, etc...) which

by using of solid or gaseous reducer (such as coke,

charcoal, anthracite, water gas, reformed natural gas,

ammonia or hydrogen decomposition) to generate

the sponge iron.

The reduction process consists of two procedures, which

are primary reduction (solid carbon reduction) and secondary

reduction.

The primary procedure mainly includes: (iron ore, rolled steel

scales, etc.) → Drying → Magnetic Separation → Crushing

→ Sieving → Canning → Entering Primary Reduction Furnace

→ Sponge Iron.

The secondary procedure includes: Sponge Iron→ Brushing

→ Magnetic Separation → Entering Secondary reduction furnace

→ becoming powder lump → crushing → magnetic separation

→ sieving → classifying → mixing →packing→finished iron

powder product.

| CAS no.: | 7439-89-6 |

|---|---|

| HS code: | 72052900 |

| Molecular Formula: | Fe |

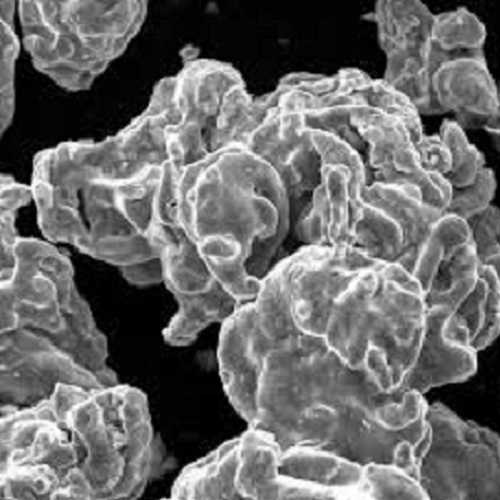

| Color: | Grey powder |

| Shape: | Irregular shape |

| Purity: | 99% |

| Certification: | ISO9001,SGS,RoHS |

| Molecular Weight: | 55.845 |

| Freezing/Melting Point: | 1537℃ |

| Boiling Point: | 2862 ℃ |

| Specific Gravity/Density: | 7.845g/cm3 |

| EINECS NO.: |

231-096-4 |

- Main material in powder metallurgy industry that consumes 60-80% of iron powder. Especially in magnetic materials.

- Welding Iron powder in the coating of welding electrode can significantly improve deposition efficiency.

- Chemical industry. It is mainly used in chemical catalysts, precious metal reduction, alloy addition & copper substitution.

- For antiseptic substance in food packing and reducing agent.

- Iron powders fine particles can be used for diamond tools.

- It's the best material used in lithium iron phosphate batteries, one of the newest energy batteries.

- Best choice for hard alloy, electric conductive slurry & rechargeable batteries.

- Water treatment

| Grade | Composition (%) | Physical Properties | Particle Size(%) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fe≥ | C≤ | S≤ | O≤ | AI≤ | P≤ | Mn≤ | Si≤ |

A.D. g/cm3 |

GD600 g/cm3 |

Flow, sec/50g |

+100 (150μm) |

+200 (75μm) |

+325 (45μm ) |

|

| CNPC-FE80 | 99 | 0.02 | 0.01 | 0.3 | 0.4 | 0.01 | 0.1 | 0.05 | 2.3-2.8 | ≥6.7 | ≤30 | ≤10 | ≤45 | 85-95 |

| CNPC-FE100 | 0.02 | 0.01 | 0.3 | 0.4 | 0.01 | 0.1 | 0.05 | ≥6.8 | ≤30 | ≤3 | ≤45 | 85-95 | ||

| CNPC-FE200 | 0.02 | 0.01 | 0.35 | 0.4 | 0.02 | 0.1 | 0.1 | 2.5-2.8 | ≥6.8 | ≤35 | - | ≤8 | ≤55 | |

| CNPC-FE300 | 0.02 | 0.01 | 0.4 | 0.4 | 0.02 | 0.1 | 0.1 | ≥6.8 | ≤38 | - | - | ≤8 | ||

| CNPC-FE400 | 0.02 | 0.01 | 0.4 | 0.4 | 0.02 | 0.1 | 0.1 | ≥6.8 | ≤40 | - | - | ≤2 | ||

| CNPC-HFE985 | 98.5 | 0.05 | 0.02 | 0.4 | 0.3 | 0.03 | 0.35 | 0.12 | 2.3-2.6 | ≥6.6 | ≤34 | ≤5 | ≤45 | 70-95 |

| CNPC-HFE98 | 98 | 0.05 | 0.02 | 0.5 | 0.3 | 0.04 | 0.4 | 0.15 | ≥6.5 | |||||

| CNPC-HFE97 | 97 | 0.1 | 0.04 | 0.8 | 0.4 | 0.06 | 0.7 | 0.3 | ≥6.2 | |||||

| Grade | Package |

|---|---|

| CNPC-Fe80 | 25KG/Package or1000KG/Ton Package |

| CNPC-Fe100 | 25KG/Package or1000KG/Ton Package |

| CNPC-Fe200 | 25KG/Package or1000KG/Ton Package |

| CNPC-Fe300 | 30KG/Box or 25KG/ Package |

| CNPC-Fe400 | 30KG/Box or 25KG/ Package |

| CNPC-Fe1000 | 30KG/Box or 25KG/ Package |

| CNPC-HFe985 | 25KG/Package or1000KG/Ton Package |

| CNPC-HFe98 | 25KG/Package or1000KG/Ton Package |

| CNPC-HFe97 | 25KG/Package or1000KG/Ton Package |

Storage Note:

中文

中文 España

España

Download

Download