- Properties

- Application

- Standard Specification

- Packing and Storage

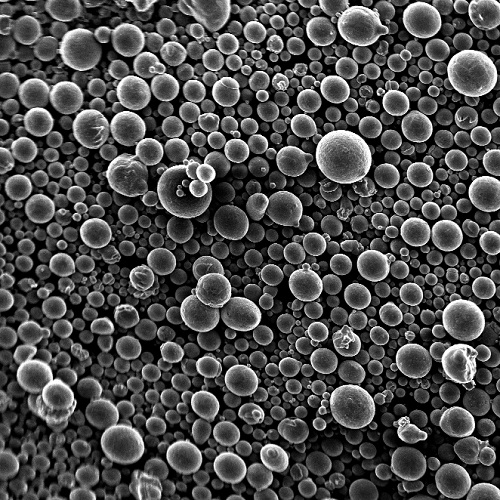

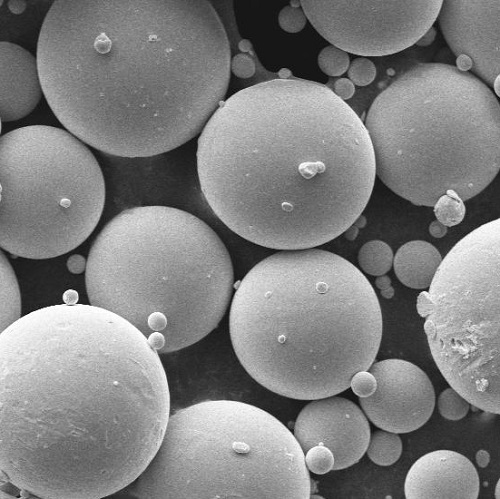

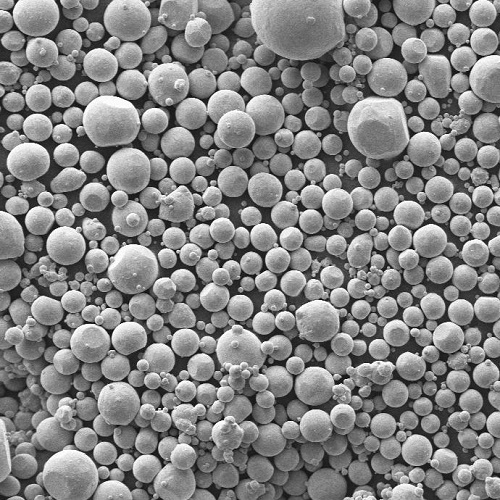

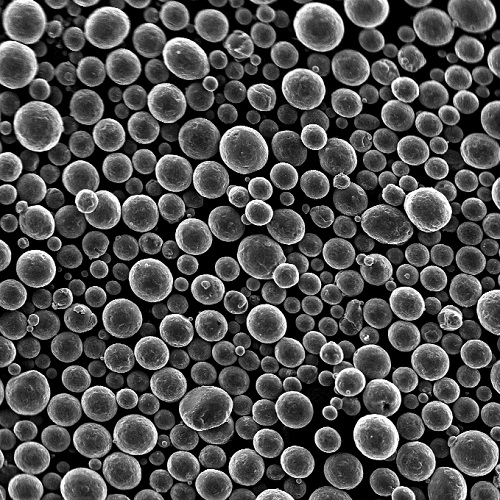

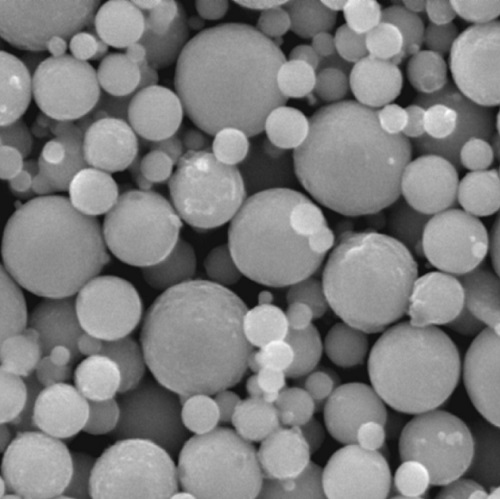

CNPC POWDER'S 3D printing refractory metal powder used argon plasma spheroidization process. The powder with lower oxygen content(<500ppm). The spherical shape with excellent fluidity. The particle distribution is very narrow. We can supply W, Mo, Ta, Nb, WCCo, etc.3D print metal powder used in aerospace, molds, automotive, medical instruments etc. CNPC POWDER supply 3D printing metal powder include Stainless Steel Powder, Nickel Alloy Powder, High Temperature Alloy Powder, Mold Steel Powder, Cobalt Alloy Powder, Aluminum Alloy, Titianium Alloy. The metal powder for 3d printing we can according to customer requirements to develop powder

3D Printing Refractory Metal Powder Production Process

Step 1: High Quality Powder Material

Step 2: Add to the nozzle

Step 3: Spheroidization

Step 4: Filter

Step 5: Collect

Step 6:Grading

Step 7: Inspection

Step 8:Packing

3D Printing Metal Powder is include Iron Alloy Powder, Aluminum Alloy Powder, Nickel Alloy Powder, Titanium Alloy Powder, Cobalt Alloy Powder.

CNPCPOWDER also could supply other metal powder in Additive Manufacture,

such as copper powder, bronze powder, tin powder, zinc powder, nickel powder,

tungsten powder, tungsten cobalt alloy powder, silver powder, etc.

- aerospace

- molds

- automotive

- medical instruments

- Military industry

| Metal Powder | Composition (%) | O (%) | A.D.g/cm3 | Particle Size | ||||

|---|---|---|---|---|---|---|---|---|

| CNPC-W | W 99.95 | <0.08 | 5.0-8.0 |

15-45um, 15-53um 20-63um, 50-150um |

||||

| CNPC-Mo | Mo 99.95 | |||||||

| CNPC-Ta | Ta 99.9 | |||||||

| CNPC-WCCo | WC 92-94 Co 6-8 | |||||||

| CNPC-Nb | Nb 99.9 | 3.5-5.0 | ||||||

| CNPC-Ni | Ni 99.9 | 3.5-5.0 | ||||||

According to customer requirements to develop powder

- Easily oxide in high temperature.

- Usually stored in tank or jar.

- Carefully keep away from moist and damp. Store in dry and ventilating place.

- vaccum package per bag for 10kg, and 20kg.

- Put the bag into drum for delivery.

中文

中文 España

España

Download

Download