- Properties

- Application

- Standard Specification

- Packing and Storage

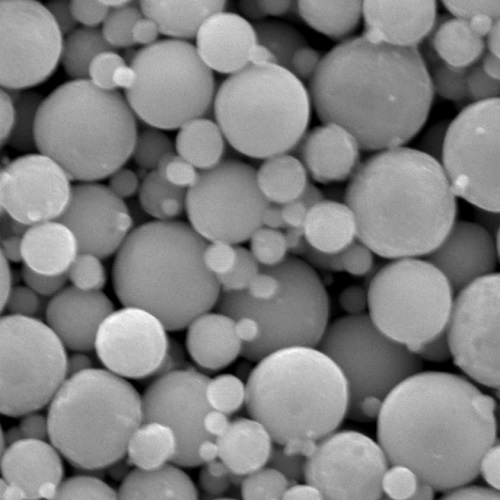

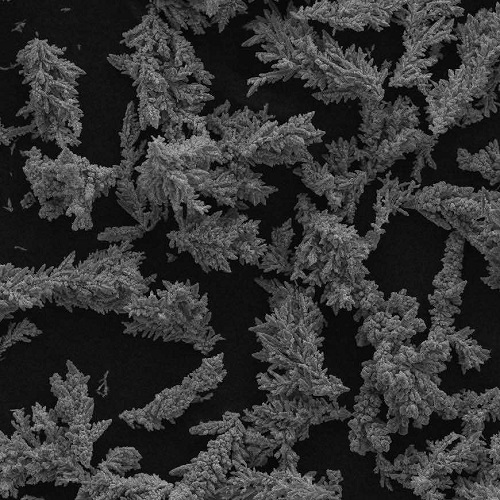

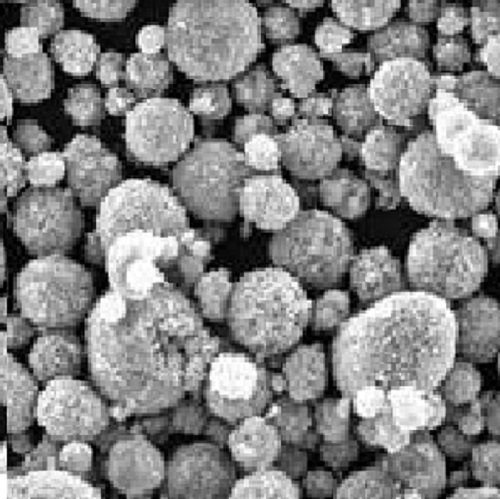

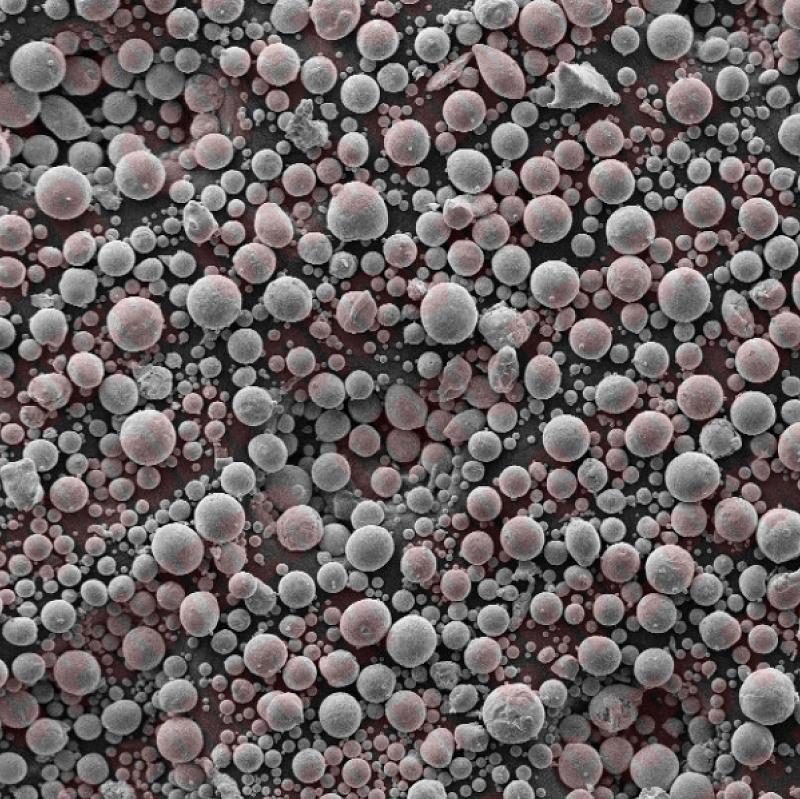

CNPC POWDER'S atomized copper powder is produced by the water atomization (pure copper powder) or gas atomized (spherical copper powder) methods. The copper powder comes in a pure fine powder form, including irregular and spherical shape. Cu content is 99.7% min. CNPC Copper powder properties of formability, inoxidizability, compressibility, sintering activity and well-developed surface are well-fitted in PM industry.

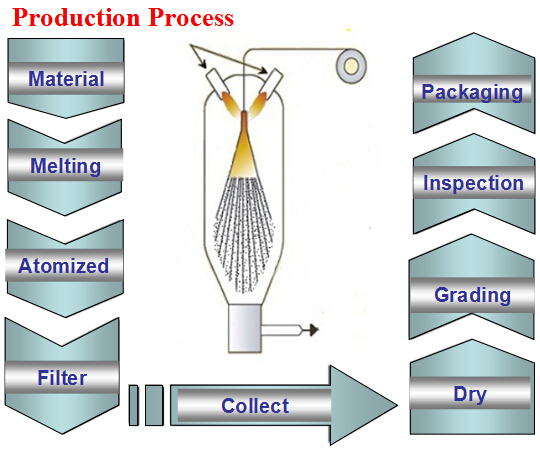

Copper Powder Production Process

Step 1: High Quality Copper Material

Step 2: Melting

Step 3: Atomized

Step 4: Filter

Step 5: Collect

Step 6: Dry

Step 7:Grading

Step 8: Inspection

Step 9:Packing

The difference between Water Atomized Copper Powder and Gas atomized Copper Powder is their apparent density, particle shape, oxygen

content and color.

Apperent Density Particle Shape Oxgyen Content Color

Water 2.3-3.5g/cm3 irregular 0.3% darker

Gas 4.5-5.2g/cm3 spherical 0.1% light

| CAS no.: | 744-50-8 |

|---|---|

| HS code: | 7406209000 |

| Molecular Formula: | Cu |

| Color: | Light Rosy |

| Shape: | Irregular or Spherical shape |

| Purity: | 99.7% |

| Product method: | Water and Gas Atomization |

| Molecular Weight: | 63.55 |

| Freezing/Melting Point: | 1083.4℃ |

| Boiling Point: | 2567 ℃ |

| Specific Gravity/Density: | 2.3-3.5g/cm3;4.5-5.2g/cm3 |

| Applicable Solubility in water: | Slightly soluble in hot water |

- Main material in powder metallurgy industry

- MIM(metla inject molding)

- 3d printing(SLM, Bind jetting etc.)

- Chemical industry for chemical reaction.

- For antiseptic substance in food packing and reducing agent.

- Fine particles copper powder can be used for diamond tools.

- Friction materials

- Electrical carbon products

- Metal injection molding

- Cold spraying and the thermal spraying

- Best choice for welding materials, hard alloy, electric conductive slurry etc.

| Grade | Composition (%) | O(%) | A.D.g/cm3 | Particle Size | ||||

|---|---|---|---|---|---|---|---|---|

| +100(150μm) | +140(106μm) | +200(75μm) | +325(45μm) | -325(45μm) | ||||

| CNPC-WCu100 | Cu99.7min | 0.3max | 2.5-3.5 | ≤5 | Bal. | ≤10 | ||

| CNPC-WCu200 | - | ≤1 | ≤5 | ≤30 | Bal. | |||

| CNPC-WCu300 | - | - | ≤1 | ≤10 | Bal. | |||

| CNPC-WCu400 | - | - | - | - | ≥95 | |||

| Grade | Composition (%) | O(%) | A.D.g/cm3 | Particle Size | ||||

|---|---|---|---|---|---|---|---|---|

| +100(150μm) | +140(106μm) | +200(75μm) | +325(45μm) | -325(45μm) | ||||

| CNPC-GCu100 | Cu99.7min | 0.1max | 4.8-5.2 | ≤5 | Bal. | ≤10 | ||

| CNPC-GCu200 | - | ≤1 | ≤5 | ≤30 | Bal. | |||

| CNPC-GCu300 | - | - | ≤1 | ≤10 | Bal. | |||

| CNPC-GCu500 | - | - | - | - | ≥95 | |||

| Grade | Package |

|---|---|

| CNPC-WCu100 | 25KG/Package |

| CNPC-WCu200 | 25KG/Package |

| CNPC-WCu300 | 25KG/Package |

| CNPC-WCu400 | 25KG/Package |

| CNPC-GCu100 | 25KG/Package |

| CNPC-GCu200 | 25KG/Package |

| CNPC-GCu300 | 25KG/Package |

| CNPC-GCu500 | 25KG/Package |

- The copper powder should stored in a cool, ventilated warehouse. Away from fire and other heart sources.

- It should be stored apart from oxidant acids, halogen ,mixed reservoir of avoiding by all means.

- Equipped with corresponding varieties and number of fire equipment.

- Storage area should be equipped with the right material for leakage content.

中文

中文 España

España

Download

Download