Material Breakthrough: Highly Thermally and Electrically Con

Date:2025-06-24

Material Breakthrough: Highly Thermally and Electrically Conductive 3D-Printable Aluminum Alloy Powder CNPC-Al0407

CNPC POWDER recently launched the highly conductive and thermally conductive 3D printing aluminum alloy powder CNPC-Al0407, which also offers excellent mechanical properties, driving innovative additive manufacturing applications in high-end industries such as aerospace, electronic heat dissipation, and new energy vehicles.

The optimized aluminum alloy powder achieves a conductivity exceeding 50% IACS and a thermal conductivity as high as 200 W/m·K. It exhibits excellent flowability and formability during 3D printing, enabling high-precision fabrication of complex structures. The material is compatible with mainstream additive manufacturing technologies, including SLM (Selective Laser Melting) and EBM (Electron Beam Melting).

Application Fields: Electronics and telecommunications, new energy industry, aerospace, and other high-end manufacturing sectors.

Product Advantages: Ultra-high conductivity, exceptional thermal efficiency, lightweight design and broad process compatibility.

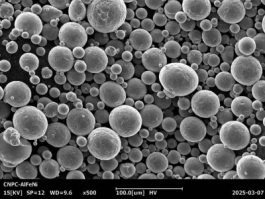

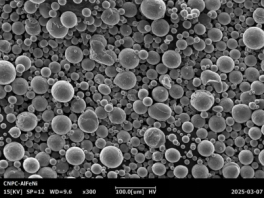

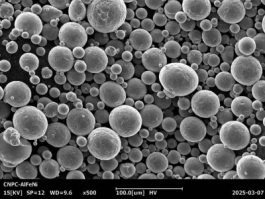

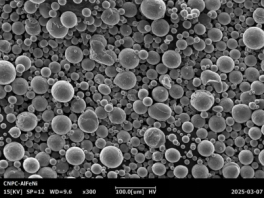

Powder Morphology

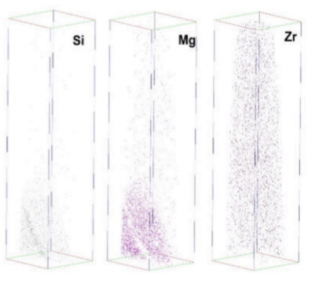

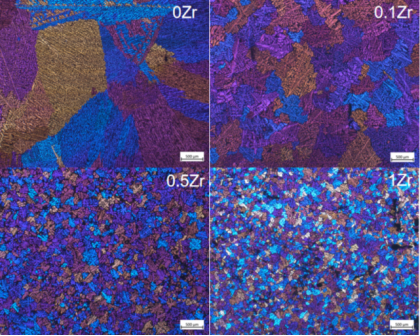

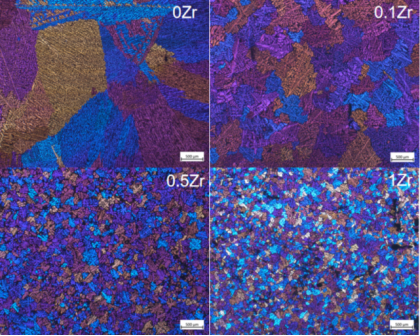

Microscopic Metallographic Structure

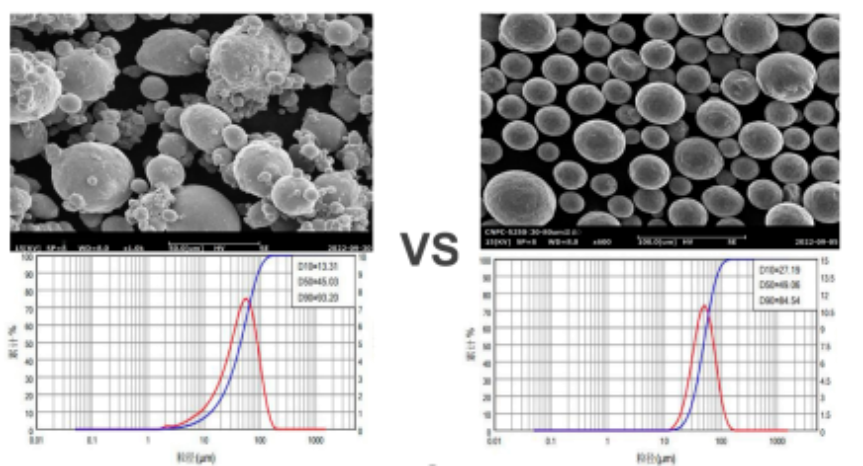

Partice Size Distribution

Thermal Conductivity

High Temperature(250℃) Tensile

Typical Properties

Outstanding Performance, Leading Cutting-Edge Applications

High Electrical Conductivity: Meets requirements for precision circuits, electromagnetic shielding, and conductive connectors.

High Thermal Conductivity: Efficient heat dissipation reduces operating temperatures, enhances device stability and lifespan, and significantly boosts system performance. Ideal for thermal-sensitive components (e.g., electronic chip heat sinks, LED cooling modules).

Lightweight Heat Dissipation: Combines excellent thermal performance with the low density of aluminum alloy. Flexible 3D printing designs enable lightweight heat exchangers for aerospace and automotive electronics.

Low Oxygen Content & High Flowability: Ensures stable printing processes, achieving part density exceeding 99.5% and reducing post-processing costs.

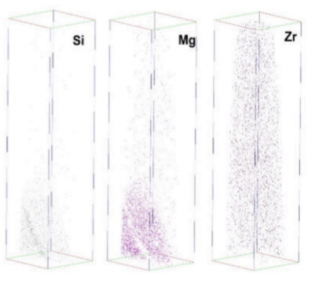

Technological Innovation Empowering Large-Scale Industrial Production

The high thermal/electrical conductivity 3D printing aluminum alloy powder CNPC-Al0407 utilizes CNPC POWDER’ proprietary AMP (Automated Metal Production) process. This technology ensures precise control of alloy composition ratios, guaranteeing consistent high performance across all production batches, while significantly enhancing production efficiency. It provides a robust foundation for industrial-scale manufacturing applications.

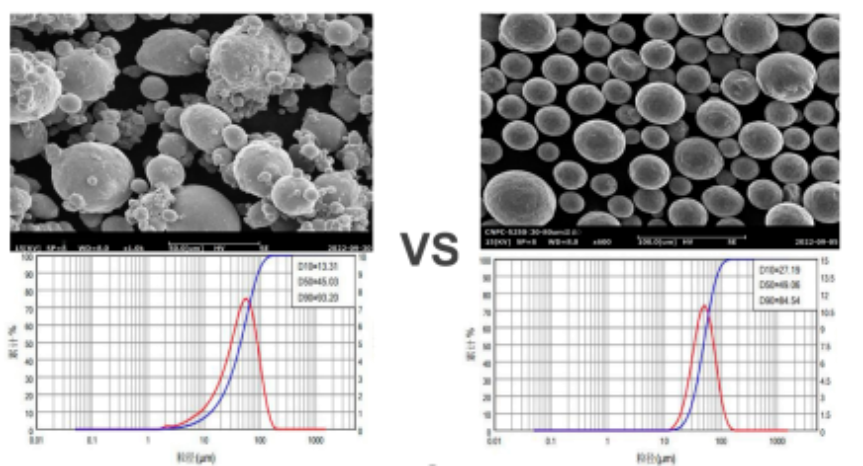

Compared to traditional gas atomization methods such as VIGA (Vacuum Induction Gas Atomization) and EIGA (Electrode Induction Gas Atomization), CNPC POEDER’ proprietary AMP production line (a novel atomization process) demonstrates significant advantages in the 3D printing metal powder market:

Ø Superior Quality: High sphericity and flowability, minimal satellite particles, and optimized printing performance.

Ø Cost Efficiency: Precise production with over 60% yield in target particle size, effectively reducing costs.

Ø High Productivity: Continuous and efficient production with shorter cycle times.

Traditional Gas Atomization CNPC POWDER AMP

CNPC POWDER recently launched the highly conductive and thermally conductive 3D printing aluminum alloy powder CNPC-Al0407, which also offers excellent mechanical properties, driving innovative additive manufacturing applications in high-end industries such as aerospace, electronic heat dissipation, and new energy vehicles.

The optimized aluminum alloy powder achieves a conductivity exceeding 50% IACS and a thermal conductivity as high as 200 W/m·K. It exhibits excellent flowability and formability during 3D printing, enabling high-precision fabrication of complex structures. The material is compatible with mainstream additive manufacturing technologies, including SLM (Selective Laser Melting) and EBM (Electron Beam Melting).

Application Fields: Electronics and telecommunications, new energy industry, aerospace, and other high-end manufacturing sectors.

Product Advantages: Ultra-high conductivity, exceptional thermal efficiency, lightweight design and broad process compatibility.

Powder Morphology

Microscopic Metallographic Structure

Partice Size Distribution

| Test Item | Test Result | Test Standard | |

| Physical properties | Apparent density(g/cm3) | >1.45 | GB/T1479 |

| Tap density(g/cm3) | >1.60 | GB/T5162 | |

| Hall flowability(s/50g) | <70 | GB/T1482-2022 | |

| PSD | D10 μm | 20-30 | GB/T19077-2016 |

| D50 μm | 38-48 | ||

| D90 μm | 60-70 | ||

|

Temperature (℃) |

Thermal Diffusivity (mm²/s) |

Thermal Conductivity [W/(m·K)] |

Specific Heat Capacity [J/(g·K)] |

Density (g/cm³) |

| 100 | 75.8 | 194 | 0.925 | 2.69 |

| 200 | 74.3 | 196 | 0.957 | |

| 300 | 72.6 | 195 | 0.975 | |

| 400 | 71.9 | 200 | 1.01 | |

| 500 | 67.8 | 201 | 1.08 |

| Testing Items | Test Results | Unit |

| Tensile strength Rm | 153 | MPa |

| Proof strength,plastic extension Rp0.2 | 141 | MPa |

| Percentage elongation after fracture A | 8.0 | % |

| Percentage reduction of area Z | 20 | % |

| Elastic modulus E | 60.5 | GPa |

| Typical Properties | As Built |

Heat Treated (250℃-2h) |

Test Standard |

| XY | XY | ||

| Ultimate tensile strength(MPa) | 248 | 227 | ASTM E8 |

| Yield strength(MPa) | 125 | 184 | |

| Elongation after break(%) | 6.5 | 9.5 | |

| Hardness(HV1) | 74.5 | 69.7 | ASTM E140 |

| Conductivity(%IACS) | 47.5 | 50.7 |

GB/T 32791-2016 |

| Thermal conductivity[W/(m·K)] | 185 | 190 | ASTM C518-04 |

| Relative density(%) | 99.96 | / | |

| Porosity % | 0.04 | ||

Outstanding Performance, Leading Cutting-Edge Applications

High Electrical Conductivity: Meets requirements for precision circuits, electromagnetic shielding, and conductive connectors.

High Thermal Conductivity: Efficient heat dissipation reduces operating temperatures, enhances device stability and lifespan, and significantly boosts system performance. Ideal for thermal-sensitive components (e.g., electronic chip heat sinks, LED cooling modules).

Lightweight Heat Dissipation: Combines excellent thermal performance with the low density of aluminum alloy. Flexible 3D printing designs enable lightweight heat exchangers for aerospace and automotive electronics.

Low Oxygen Content & High Flowability: Ensures stable printing processes, achieving part density exceeding 99.5% and reducing post-processing costs.

Technological Innovation Empowering Large-Scale Industrial Production

The high thermal/electrical conductivity 3D printing aluminum alloy powder CNPC-Al0407 utilizes CNPC POWDER’ proprietary AMP (Automated Metal Production) process. This technology ensures precise control of alloy composition ratios, guaranteeing consistent high performance across all production batches, while significantly enhancing production efficiency. It provides a robust foundation for industrial-scale manufacturing applications.

Compared to traditional gas atomization methods such as VIGA (Vacuum Induction Gas Atomization) and EIGA (Electrode Induction Gas Atomization), CNPC POEDER’ proprietary AMP production line (a novel atomization process) demonstrates significant advantages in the 3D printing metal powder market:

Ø Superior Quality: High sphericity and flowability, minimal satellite particles, and optimized printing performance.

Ø Cost Efficiency: Precise production with over 60% yield in target particle size, effectively reducing costs.

Ø High Productivity: Continuous and efficient production with shorter cycle times.

Traditional Gas Atomization CNPC POWDER AMP

下一篇:没有了

News

中文

中文 España

España