CNPCPOWDER has may different method for producing powders. The mail technologies include gas atomized(VIGA,EIGA), water atomized, plasma atomized(PA), plasma spheroidization(PS), plasma rotating electrode(PREP), Plasma vaporing deposition(PVD),Pulverzing method etc..

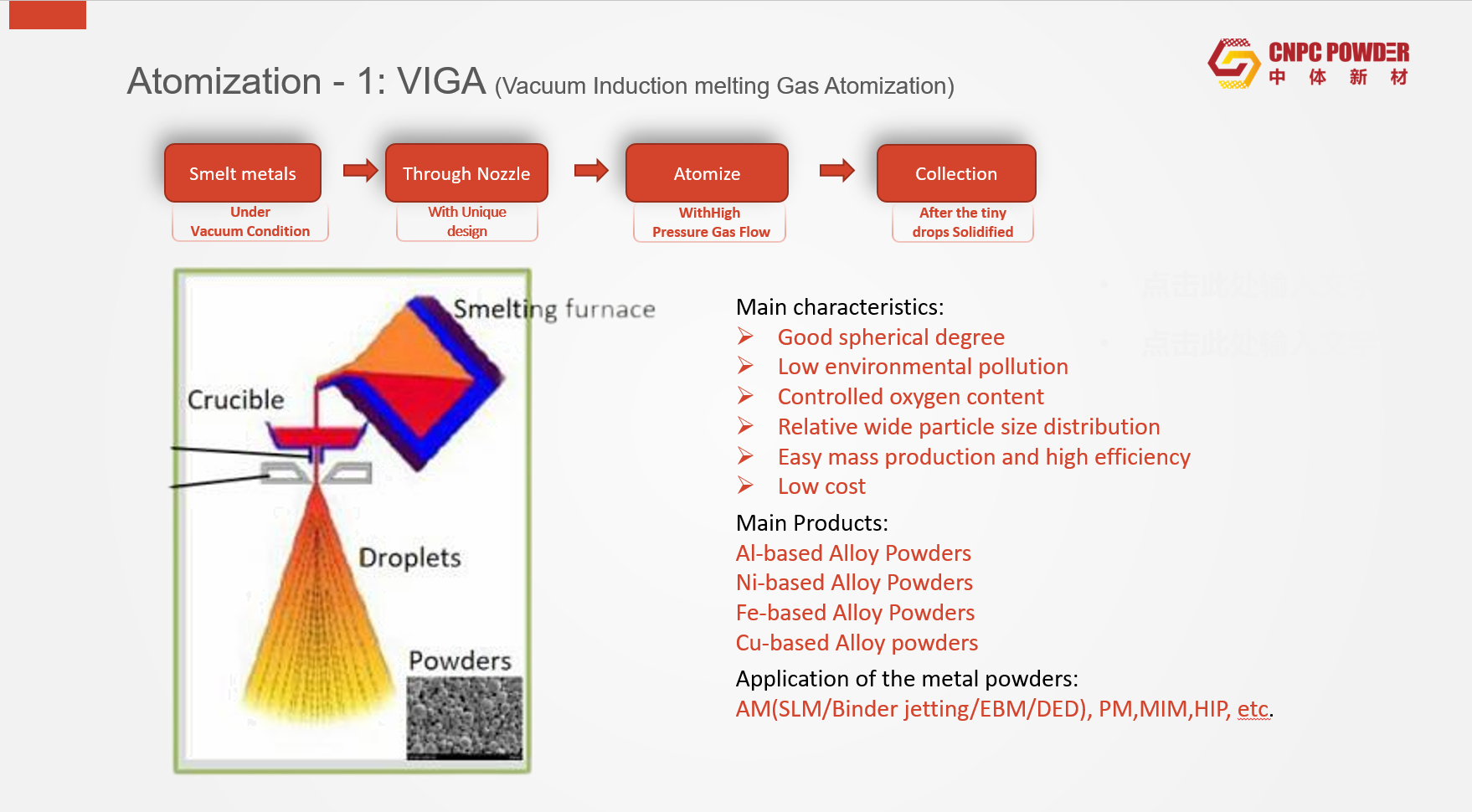

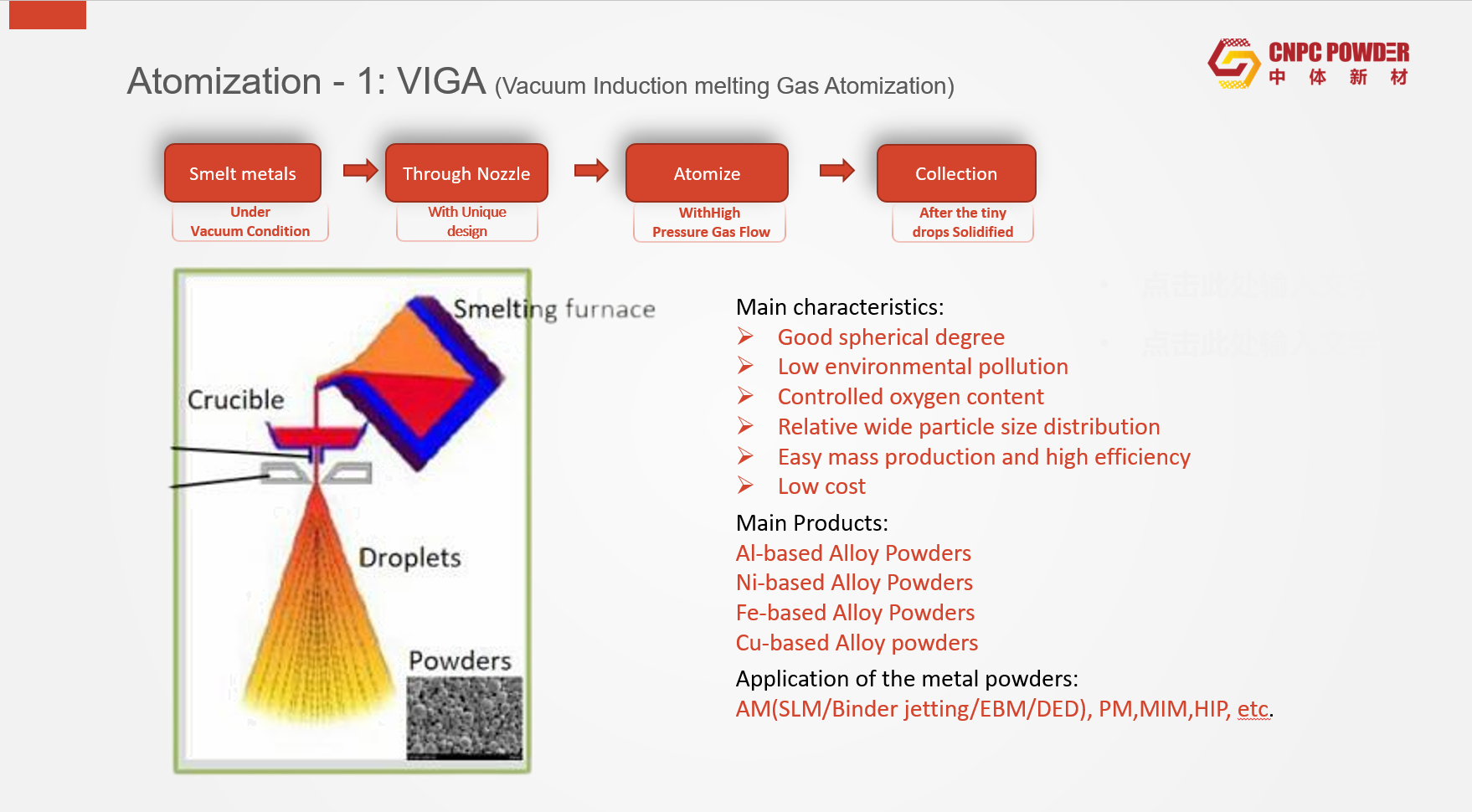

Gas atomizing Process (VIGA, EIGA)

First the coarse metarial or ingot is melted in the furnace to get liquid metal. Then the liquid metal is turned into droplets. Then we cool the liquid and collect the powder.Then sieve the powder and separate.We then collect the elaborate powder and mix them. At last we package the fashioned powder.

Plasma Spheroidization Process (PS)

Plasma Rotating Electrode Process (PREP)

Plasma Vaporing Deposition (PVD)

First used the raw metarials add into crusible, used plasma with high temperature let the raw material form solid to gas. The add cold Argon or Nitrogen. The raw material gas deposition into tiny solid powder. Finally we sieve the powder.and mix them for packaging.

Plasma Vaporing Deposition---raw material---Heat treatment--deposition---Sieving---Mixing---packaging

Electrolytic Process First use the electrolytic process to get the powder and the then washing the powder and use vacuum drying. We then sieve the powder and classifiton them, and then mixing the powder for packaging.

Electro Deposition---Washing---Drying---Sieving---Mixing---Packaging

Pulverizing Method There are five methods we can sue to create metal power;Jaw crusher, Jet mill, Hammer Mill, Ball Mill Agitating, Attriction Mill.

Reduced Process First we use the chemical reduction method, single reduction and second reduction get the powder and then washing them and drying the sieving them.Then magnetic concentration and then mixing the filtered and packaging the fashioned powder.

Chemical Reduction---Washing---Drying---sieving---mixing---packaging

Gas atomizing Process (VIGA, EIGA)

First the coarse metarial or ingot is melted in the furnace to get liquid metal. Then the liquid metal is turned into droplets. Then we cool the liquid and collect the powder.Then sieve the powder and separate.We then collect the elaborate powder and mix them. At last we package the fashioned powder.

Water Atomizing Process

First the coarse metarial or ingot is melted in the furnace and we get liquid metal. Then use the atomizer with metal liquid to break it down into tiny droplets. Then drying and collecting the powder. We then use heat-treatment,then a furnace to dry the wet powder. Finally we sieve the powder.and mix them for packaging.

Water Atomization---drying---Heat treatment---Sieving---Mixing---packaging

Plasma Atomizing Process (PA)

First used the wire metarial add into the tank, then the plasma jetting high temperature gas with the melting wire metarial. Then the metal liquid to break it down into tiny droplets. Finally we sieve the powder.and mix them for packaging.

Water Atomization---drying---Heat treatment---Sieving---Mixing---packaging

Plasma Atomizing Process (PA)

First used the wire metarial add into the tank, then the plasma jetting high temperature gas with the melting wire metarial. Then the metal liquid to break it down into tiny droplets. Finally we sieve the powder.and mix them for packaging.

Plasma Spheroidization Process (PS)

First used the powder metarials(15-53um) add into the plasma tank, then the plasma high temperature metal the powder surface, The powder particles are shrunk by surface tension to spherical particles. Finally we sieve the powder.and mix them for packaging.

Plasma Rotating Electrode Process (PREP)

First used the bar metarials add into the plasma flame, then the material matel into liquid. rotating the bar mateial with high speed. Depand on centrifugal force break it down into tiny droplets. Finally we sieve the powder.and mix them for packaging.

Plasma Vaporing Deposition (PVD)

First used the raw metarials add into crusible, used plasma with high temperature let the raw material form solid to gas. The add cold Argon or Nitrogen. The raw material gas deposition into tiny solid powder. Finally we sieve the powder.and mix them for packaging.

Plasma Vaporing Deposition---raw material---Heat treatment--deposition---Sieving---Mixing---packaging

Electrolytic Process First use the electrolytic process to get the powder and the then washing the powder and use vacuum drying. We then sieve the powder and classifiton them, and then mixing the powder for packaging.

Electro Deposition---Washing---Drying---Sieving---Mixing---Packaging

Pulverizing Method There are five methods we can sue to create metal power;Jaw crusher, Jet mill, Hammer Mill, Ball Mill Agitating, Attriction Mill.

Reduced Process First we use the chemical reduction method, single reduction and second reduction get the powder and then washing them and drying the sieving them.Then magnetic concentration and then mixing the filtered and packaging the fashioned powder.

Chemical Reduction---Washing---Drying---sieving---mixing---packaging

中文

中文 España

España