- Properties

- Application

- Standard Specification

- Packing and Storage

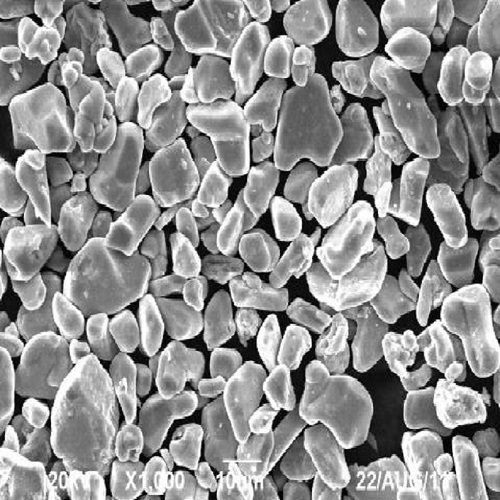

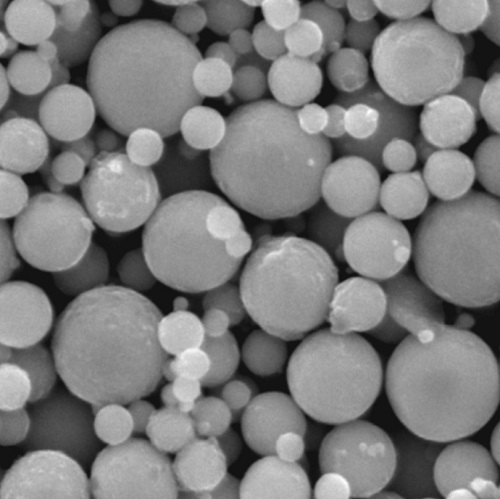

CNPC POWDER© is an experienced stainless steel powder manufacturer and supplier, with a range from SS304 to SS430L, including basic austenitic grade, martensitic grade and ferritic grade. All these Stainless Steel powder have two different shapes: irregular and spherical.

| CAS no.: |

52013-36-2 |

|---|---|

| HS code: |

7205210000 |

| Mean size |

<33um |

| Color: |

Grey black powder |

| Shape: |

Spherical form or irregular form |

| Type: |

304,304L,316,316L,410L,430L |

| Product method: |

Water atomized and Gas atomized |

| Specific Gravity/Density: |

7.9g/cm3 |

What are stainless steels:

Iron-base alloys containing different sufficient CHROMIUM to form a stable passive film on the surface.

10.5% is the qualifying concentration of Cr for an alloy to be called Stainless Steel.

What makes stainless steel “stainless”:

With sufficient chromium(>10.5%), the steel is able to form a protective film on the surface (passivate) in aqueous environments.

Properties of Austenitic(316,316L): (L means C﹤ 0.03%)

Excellent resistance to corrosion

High toughness and good buctility

Moderate strength, hardenable by cold work

High resistance to oxidation at elevated temperature

Low thermal conductivity

High coefficient of thermal expansion

Non-magnetic Not heat treatable

Alloying elements: Cr, Ni, (Mo) min 9%

Properties of ferritic:

-

Low to moderate corrosion resistance

Moderate strength & ductility

Magnetic, not heat treatable

Marginal high temp strength & oxidation resistance

Higher thermal conductivity

Lower coefficient of thermal expansion

Low-cost option with functional corrosion resistance

Alloying elements: Cr(Mo, Nb)

Stainless Steel Powder 316/316L Application suggest:

3D printing (spherical shape). Applied to the pressed and sintered powder metallurgy (PM); injection molding; sintered filter; chemical fiber spinning filter material.

Why use stainless steel:

- Corrosion resistance

- Oxidation resistance

- Elevated temperature mechanical strength

- Room temp mechanical strength, toughness

- Low-cost wear resistant material (with 410)

- Magnetic behavior with ferritic

| Grade | Composition (%) | O (%) | A.D.g/cm3 | Particle Size | ||||

|---|---|---|---|---|---|---|---|---|

| CNPC-SS304 | Cr18-20, Ni8-12, C 0.08 | 0.45max | 3.5-5.0 |

100mesh, 200mesh, 300mesh, 400mesh; D50:9-12μm, D50 3-5um, D50 1-2um,D50 0.501um |

||||

| CNPC-SS304L | Cr18-20, Ni8-12, C 0.03 | |||||||

| CNPC-SS316 | Cr16-18, Ni10-14, Mo2-3, C 0.08 | |||||||

| CNPC-SS316L | Cr16-18, Ni10-14, Mo2-3, C 0.03 | |||||||

| CNPC-SS410L | Cr11.5-13.5, C 0.03 | 4.0-5 | ||||||

| CNPC-SS430L | Cr16-18, C 0.05 | 3.5-4.5 | ||||||

| Grade | Package |

|---|---|

| CNPC-SS304 | 25KG/Package |

| CNPC-SS304L | 25KG/Package |

| CNPC-SS316 | 25KG/Package |

| CNPC-SS316L | 25KG/ Package |

| CNPC-SS410 | 25KG/ Package |

| CNPC-SS420 | 25KG/ Package |

| CNPC-SS430 | 25KG/ Package |

- Easily oxide in high temperature.

- Usually stored in tank or jar.

- Carefully keep away from moist and damp. Store in dry and ventilating place.

中文

中文 España

España

Download

Download