- Properties

- Application

- Standard Specification

- Packing and Storage

CNPC POWDER utilizes the best material with the lowest impurity in China. After the material goes through serval processes with very strict quality control the powder material becomes highly pure iron powder (99.5%-99.7%) with an extremely low impurity content of C, Si, Mn, P and S.

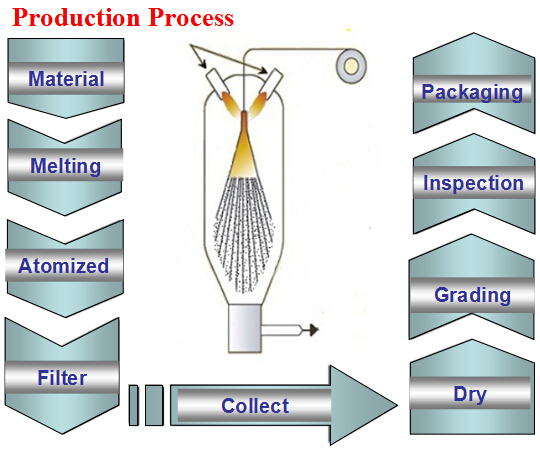

atomized Iron powder Production Process

Step 1: High Quality iron material

Step 2: Melting

Step 3: Atomized

Step 4: Filter

Step 5: Collect

Step 6: Dry

Step 7: Grading

Step 8: Inspection

Step 9: Packing

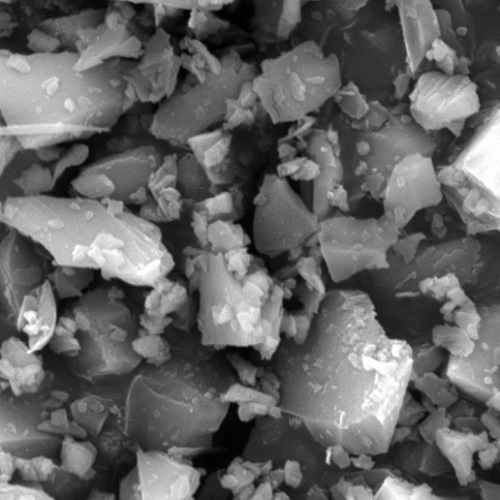

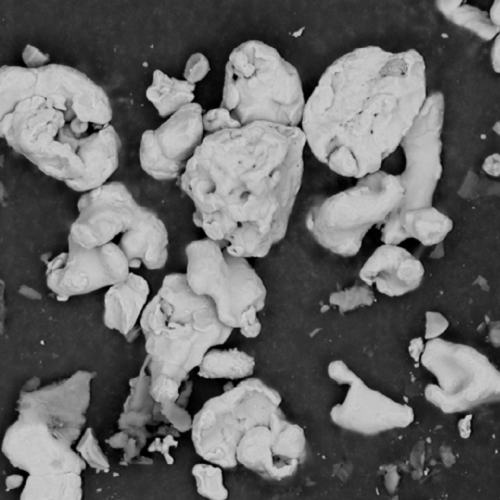

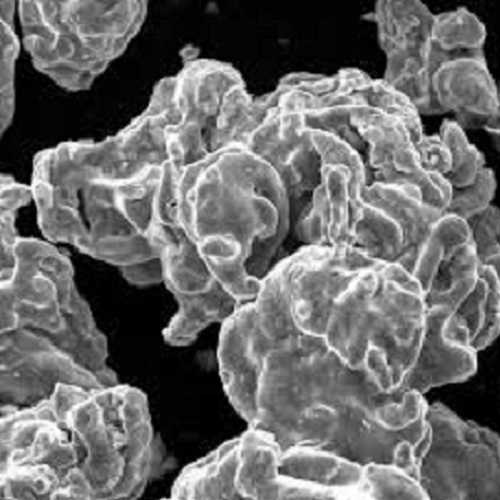

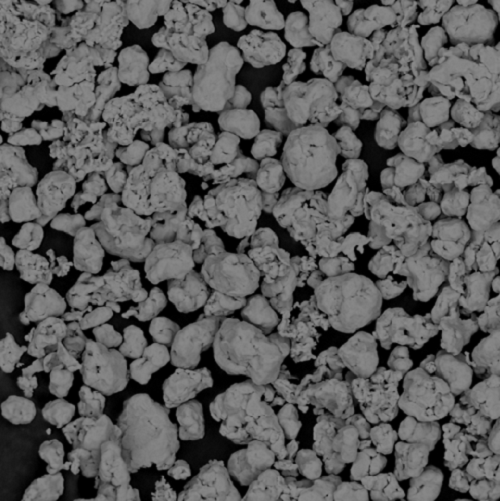

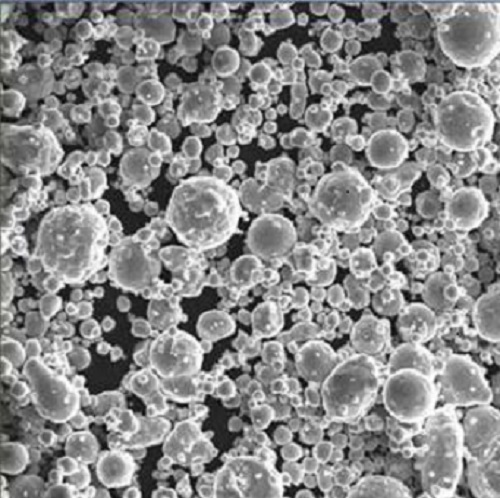

Atomized Iron Powder is relatively pure with irregular particles that are

produced by the atomization method. We also can supply spherical iron powder.

CNPC Atomized iron powder is the best material that can be used for suppressing

mechanical parts or structural parts and it is also some of the best welding material.

Metal Powder Material Blending is base on pure iron powder to add copper powder,nickel powder,molybdenum powder,manganses powder,manganese sulfide,graphite,lubricant,etc.We can according to customer requirements to

mixing blending powder.

MPIF 35(Sintered Iron and Sintered-Carbon Steel)

F-0000,F-0005,F-0008,FC-0200,FC-0205,FC-0208,FC-0505,FC-0508,FC-0808

FC-1000,FC-2000,FC-2008,FD-0200,FD-0205,FD-0208,FD-0405,FD-0408,etc.

| CAS no.: | 7439-89-6 |

|---|---|

| HS code: | 72052900 |

| Molecular Formula: | Fe |

| Color: | Grey powder |

| Shape: | Irregular or drop Shape |

| Purity: | 99.5%-99.7 |

| Certification: | ISO9001,SGS,RoHS |

| Molecular Weight: | 55.845 |

| Freezing/Melting Point: | 1537℃ |

| Boiling Point: | 2862 ℃ |

| Specific Gravity/Density: | 7.845g/cm3 |

| EINECS NO.: |

231-096-4 |

- Main material in powder metallurgy industry. Especially in structural parts.

- Chemical industry for chemical reaction.

- For antiseptic substance in food packing and reducing agent.

- Fine particles iron powder can be used for diamond tools.

- It's best material used in lithium iron phosphate batteries that one of a new energy battery.

- Best choice for welding materials, hard alloy, electric conductive slurry, rechargeable battery etc.

| Grade | Composition (%) | Physical Properties | Particle Size(%) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fe≥ | C≤ | S≤ | O≤ | AI≤ | P≤ | Mn≤ | Si≤ |

A.D. g/cm3 |

GD600 g/cm3 |

Flow, sec/50g |

+100 (150μm) |

+200 (75μm) |

+325 (45μm) |

|

| CNPC-AFE100 | 99.5 | 0.01 | 0.01 | 0.15 | 0.1 | 0.01 | 0.08 | 0.03 | 2.9-3.1 | ≥7.1 | ≤25 | ≤4 | ≤45 | 65-85 |

| CNPC-AFE200 | 0.01 | 0.02 | 0.2 | 0.2 | 0.01 | 0.12 | 0.05 | - | - | - | ≤8 | - | ||

| CNPC-AFE300 | 0.01 | 0.02 | 0.23 | 0.2 | 0.01 | 0.12 | 0.05 | - | - | - | - | ≤8 | ||

| CNPC-FE40.30 | 99 | 0.01 | 0.01 | 0.2 | - | 0.01 | 0.12 | 0.05 | 2.9-3.2 | - | - | ≤90 | - | - |

| CNPC-FE40.37 | 3.5-3.8 | |||||||||||||

Blending powder

F-0000,F-0005,F-0008,FC-0200,FC-0205,FC-0208,FC-0505,FC-0508,FC-0808,FC-1000,FC-2000,FC-2008,FD-0200,FD-0205,FD-0208,FD-0405,FD-0408,etc.

| Grade | Package |

|---|---|

| CNPC-AFe100 | 25KG/Package or1000KG/Ton Package |

| CNPC-AFe200 | 25KG/Package or1000KG/Ton Package |

| CNPC-AFe300 | 25KG/Package or1000KG/Ton Package |

| CNPC-Fe40.30 | 25KG/Package or1000KG/Ton Package |

| CNPC-Fe40.37 | 25KG/Package or1000KG/Ton Package |

Storage Note:

The iron powder should be stored in a cool, dry, well ventilated warehouse and kept away from fire and other heat sources. Relative humidity should remain below 75%. The packing must be sealed, do not be affected with damp . It should be kept apart from alkali, alcohol, and it should avoid mixed reservoir by all means. The storage area should be equipped with the right material in the case of leakage.

中文

中文 España

España

Download

Download